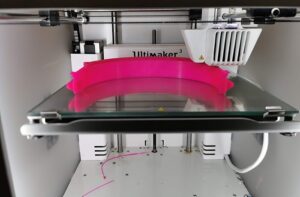

A Nantwich company has appealed for 3D printers so they can expand their production of face shields for NHS staff on the COVID-19 pandemic frontline.

Gateway Electronic Components, on Beam Heath Way, has have started 3D printing face shields to help in the crisis and is running machines 24 hours a day.

But they are keen to expand capacity and are calling on anyone who has a 3D printer to let them use it for a few weeks.

Gateway Electronics technical manager Josh Bailey said: “We will provide all filaments and programmes, so it won’t cost the owners anything.

“The NHS needs your 3D printer!”

Josh says the company has all its machines running to full capacity but on average one shield takes 1.5 hours to print.

“We want to expand capacity,” he added.

“If you own a 3D printer with a minimum build plate of 200 x 200 x 30mm and are willing to help, Gateway are simply asking you to drop your 3D printer off at our office in Nantwich.

“We will provide all filaments and programs and have the capability to run your machine 24/7.”

It’s the latest example of local companies pitching in to help NHS staff and key workers in the coronavirus pandemic.

We revealed yesterday how breakfast cereal firm Mornflake has been donating large amounts of breakfast oats to key workers across the UK.

And distribution transport firm Boughey have increased its deliveries to supermarkets across the UK with 50 extra journeys a day to help keep shelves stocked.

If you can help Gateway with a 3D printer, contact Josh Bailey to see if your machine is suitable and arrange a drop off on 01270 615999 or email [email protected]

Hi

Carl from gorilla 3d here do you want to send me the stl and all the info we need. At the moment we’ve got a flashforge guider 2 available that’s got a bed area of 280 x 250 x300. Waiting for delivery of our new optimus p1 and creality cr1s Pro